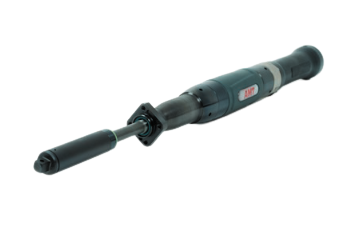

BATTERY-POWERED SCREWDRIVER HCXB

Pistol grip nut runners

- Torque to 11 Nm

- Speed to 476 1/min

Angle Nut Runners

- Torque to 64 Nm

- Speed to 587 1/min

Fixture nut runners

- Torque to 27 Nm

- Speed to 913 1/min

Important Features

Ergonomics, power and torque accuracy are the requirements for the automobile and tier supplier industry. The mobile battery-powered tools from AMT fulfill these requirements and even more. By using a proven, highly-dynamic motor, it is now possible to achieve high performance indicators despite low tool weight. The appealing design was made under the aspect of trend-setting ergonomics:

- Ergonomic handle.

- Newly designed switch ring for right/left operation with additional freely assignable switch function. (e.g. NIO acknowledgment, program selection…)

- Status display with display of the selected rotation direction through LEDs and additional LED for advanced display functions. (e.g. NIO acknowledgment, approval)

- Ergonomic, conveniently placed start button made of electro-polished stainless steel.

- One-piece, ergonomically formed angle head (can be rotated by 4 x 90°)

Low weight through light construction.

Integrated Data Chip

Of course, the battery-powered tools also have an integrated data chip in which all relevant tool data is saved by the factory. This data is automatically imported by the AMT controller as soon as a new tool is reported to the controller. Therefore, laborious parameterization is a thing of the past. The tool also saves the number of executed fastening cycles. This allows for the development of individual maintenance concepts for preventive maintenance.

Error Proof Assembly

All battery-powered tools have a reaction-torque sensor to measure the torque as well as a recording of the rotational angle through hall sensors. Therefore, fastening can be done with the highest precision with consistent quality. Through the angle detection, it is also examined to see if the defined torque was actually used on the same fastener within the assembly. All battery-powered tools additionally monitor the power intake equivalent to the torque as a redundant control variable. Thus, all requirements that are placed in the assembly of safety-relevant or quality-critical assemblies are fulfilled.

Integrated Barcode Scanner

Before the assembly process, initially the tool must often be identified through a barcode scanner. Based on the piece number, the correct assembly program is activated by the nut runner control and the piece number and the assembly data can be filed together in a quality database. However, scanning a barcode with a separate barcode scanner is a time-intensive process. That is why AMT integrated the barcode scanner in the tool. Scanning and fastening are now one step. The cycle time reduction resulting from this also reduces the assembly costs.

Wireless Data Transmission

The data transmission between the tool and controller occurs through a wifi module. Secure data transmission is guaranteed through encryption.