Tightening technology of tomorrow

The new tightening generation from AMT Customer benefits

- User Friendly Operation.

- Easy Programming.

- Minimum training time and costs.

- Efficient Fault Diagnostics.

- Reduced Energy Costs

Introduction Controller

SMX-C

- 7 Seg. Display

- 4 status LEDs

- T. Controller

- Webserver

SMX100

- 7 Seg. Display

- 4 status LEDs

- T. Controller

- Webserver

SMX300

- 6,5“ Display

- T. Controller

- PC

- Webserver

SMX400

- 10“ Display

- T. Controller

- PC

- Webserver

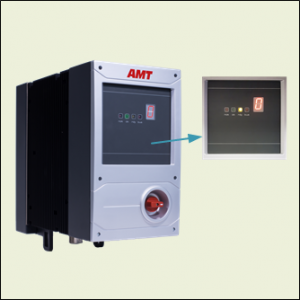

Advantages of the integrated Webserver

- Enables communication with mobile devices.

- Parameterization, production screen And diagnostic analysis aia web browser.

- No additional parameterization software necessary. As a result no software version problems between parameterization software and the firmware on the controller.

User- friendly operation

Tools for parameterization

- Library Function.

- Programming Assistant.

- Graphical Programming.

User friendly service support

Easy programming, efficient fault diagnosis, high availability

- Every action is now possible regardless of location and time.

- If, for example, the maintenance person is notified of a fault via email, he can access the AMT controller directly with his mobile device. This convenient operation saves time and money.

- Another innovation is the QR code attached to the AMT controller. If it is scanned by a mobile device, the connection is established automatically to the controller.

- Fast and uncomplicated, the maintenance technician can now change the crucial parameters.

Types of Tools

KSX…

- Mini Fixtured Tools

- 3 Nm – 110 Nm

ESX…

- Fixtured Tools

- 4 Nm – 1300 Nm

HSX…

- Angle head tool

- 5 Nm – 250 Nm

PSX…

- Pistol Grip Tool

- 3 Nm – 90 Nm

HCXBW…

- Angle head tool

- 5 Nm – 97 Nm

PCXBW…

- Pistol Grip Tool

- 3 Nm – 40 Nm

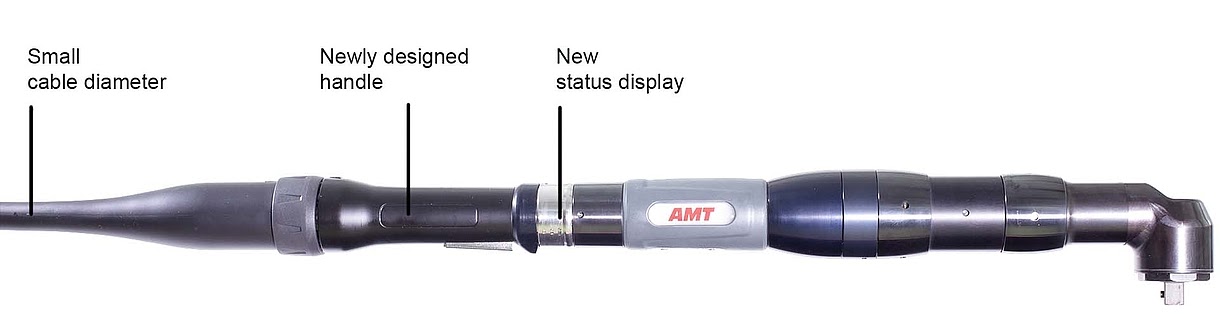

Handheld Nut runner HSX – The new smart tools

Together with the new HSX handheld nut runners, a completely newly developed control generation was implemented. This makes it possible to now program and monitor the tool with mobile devices like tablets or Smartphone

- Digital data transmission between handheld nut runner and control.

- Tool cable with significantly reduced number of wires, this makes the cable light and smaller bending angles are possible.

- New hybrid plug system with improved protection against the plug being loosened and improved bend protection.

- Hot plug and play, this means the nut runner can be plugged in and out of the controller without the controller having to first be turned off.

- Better ergonomics through the newly designed handle and easier to read status display.

- New status display with display of the selected rotational direction through LEDs and additional LEDs for advanced display functions.(for example, NIO acknowledgment, approval)

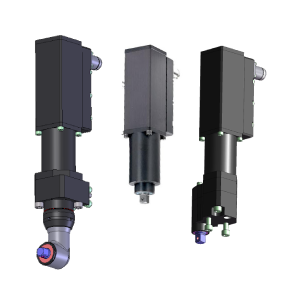

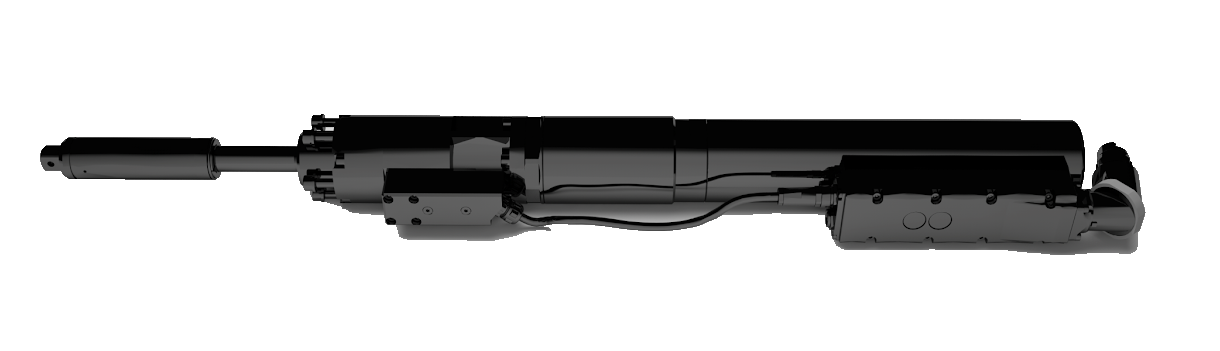

Fixture Nutrunners ESX

- Status indicator via LED´s.

- fully digital signal transmission to the controler.

- Swivel connection: One cable for all the different tools.

Fixture Nutrunners ESX

Inline Output

- Torqueto 1.300 Nm

- Speedto 1.200 1/min

Offset Output

- Torqueto 1.000 Nm

- Speedto 1.114 1/min

Angle Output

- Torqueto 800 Nm

- Speedto 1.136 1/min