DSM Product Range

Built-in EC Nutrunners

DSM's built-in EC nutrunners deliver exceptional precision and reliability for automated assembly applications. With maintenance-free brushless servo motors and robust housings made of stainless steel and aluminum, these nutrunners are designed for longevity in industrial environments.

Key Features:

-

Digital tightening technology with exceptional precision

-

Error-free setup through integrated parameter memory

-

Clockwise/anti-clockwise operation

-

Diverse drive and attachment versions

-

Torque ranges from 0.05 Nm to 2400 Nm

Available Models:

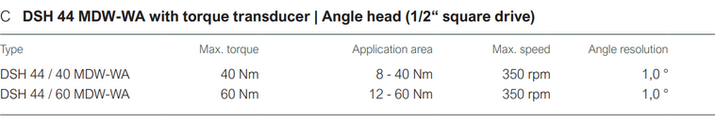

Hand-held Nutrunners (DSH Series)

DSM's hand-held nutrunners combine ergonomic design with digital precision for manual assembly operations. With integrated parameter memory and maintenance-free servo motors, these tools ensure consistent quality in manual tightening applications.

Key Features:

-

Digital hand-held tightening technology

-

Torque ranges from 0.05 Nm to 60 Nm

-

Error-free setup through integrated parameter memory

-

Wear-free operating elements

-

Robust housing made of stainless steel and aluminum

Available Models:

DSH26 Hand-held nutrunner with electronically controlled servo motor and digital data transmission. Available in torque versions 0.5 Nm, 1 Nm, 2 Nm and 4 Nm.

DSH Hand-held nutrunner with electronically controlled servo motor and digital data transmission.

DSM Digital Press-In Technology

In the field of electromechanical press-in units, DSM covers a press-in force range of 50 N to 120,000 N. In line with requirements, we equip the press-in units with a greater stroke, return stop or electromechanical brake.

Application Fields

-

Our press-in technology is suitable for a wide range of precision applications:

-

Precision press-in

-

Press-in to a stop

-

Riveting

-

Bending

-

Embossing/forming

-

Testing/measuring

-

Caulking

-

Clipping

-

Checking switch/latch points

-

Calibrating

Product Series

QMP-Series

-

The DSM QMP Series is compactly built including:

-

Force sensor

-

Press-in stamp

-

Absolute distance measuring system

-

Built-in LED status indicator

Combined with the MultiPro 3G control system, a high assembly accuracy and uninterrupted documentation of production data is guaranteed.

The entire system is powered by a brushless, electronically controlled servo motor.

XMP-Series

The DSM XMP Series is distinguished by a flexible design ensuring tremendous modularity.

A flexible solution for both simple and complex tasks is guaranteed thanks to following components:

-

Integrated gear module

-

Variable and highly accurate force sensor

-

Absolute distance measuring system

-

Large illuminated field

-

MultiPro 3G control system

XMP press-in units are powered by a brushless electronically controlled servo motor.

Thanks to the modular structure, additional components can be added:

-

Motor holding break (MB)

-

Backstop (RS)

-

Holding brake (HB)

Force Capabilities

The XMP press-in technology is designed for:

-

Tensile forces

-

Compressive forces

This versatility allows for push and pull operations within the same system, maximizing the utility of your investment.

Controller

All DSM press-in systems are controlled by the advanced MultiPro 3G controller, featuring:

-

5.7 inch touch color display with intuitive menu navigation

-

Graphic display of measured values with zoom function

-

12 status LEDs for clear operation feedback

-

Comprehensive programming capabilities

-

Automatic self-test and calibration functions

-

Data storage and analysis tools

-

Network connectivity via TCP/IPSystem bus interface for accessories and multi-controller networking

Benefits of DSM Digital Press-In Technology

-

Precision: Exact control of force and position

-

Documentation: Complete traceability of all operations

-

Flexibility: Adaptable to various applications with modular design

-

Reliability: Robust construction for industrial environments

-

Integration: Seamless connectivity with production systems

-

Quality Assurance: Real-time monitoring and validation

Contact Us for Demo!

312, SIDCO- AIEMA Tower,

1st Main Road

Ambattur Industrial Estate, Chennai - 600058, Tamil Nadu, India

+91-44-2624664, 42060510